-

Rite-Hite unveils new range of hydraulic kits to upgrade and extend dock leveller performance - February 19, 2026

-

REWE and Cimcorp automate fresh supply chain for Berlin supermarkets and stores - February 19, 2026

-

Q1 – A recovery period or time to fix, switch and scale? - February 19, 2026

-

NULOGY’S SHOP FLOOR SOFTWARE TO POWER COMPLETE CO-PACKING’SOPERATIONS - February 13, 2026

-

Why lead generation depends upon good content - February 13, 2026

-

Wallapop and Albatross Sign Strategic Partnership to Bring Real-Time AI Discovery to the Future of Consumer-to-Consumer Commerce - February 12, 2026

-

Thorworld ramp helps Hubergroup to streamline its unloading operation - February 6, 2026

-

TRACKER INNOVATION FROM QUECLINK TO BOOST STOLEN VEHICLE RECOVERY PERFORMANCE - February 4, 2026

-

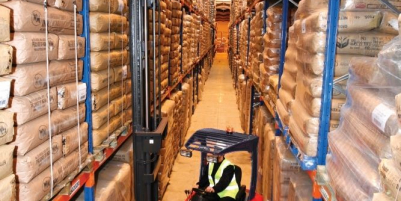

Flexi Narrow Aisle hits 50! - January 29, 2026

-

DERRY BROS ATTRACTS RECORD NUMBERS OF FREIGHT CUSTOMERS SEEKING CUSTOMS SUPPORT - January 29, 2026

Leading contract packer APS has successfully migrated to Nulogy’s advanced and flexible cloud-based software for co-packers, enabling it to respond more quickly and effectively to customer demands.

Given the constraints of lockdown, Nulogy implemented the solution entirely remotely, handling the change management process from APS’s legacy systems through a combination of video-based conferencing and its robust online learning platform, Nulogy University.

Based in the North East of England, APS is a well-established market leader in contract packing, working with blue chip brands since its formation. The business had been using a combination of manual processes and ERP systems and recognised the need to improve traceability and visibility of materials and labour productivity across its operations.

David Howes, operations director at APS, said: “To execute successfully on our growth strategy for the business, it was clear that we had to modernise our systems. Nulogy presented a clear vision of the benefits available from digitalisation through its cloud-based solution, and while we had some concerns about migrating to a new software system virtually during a pandemic, the team at Nulogy made the transition possible with continued support and guidance throughout.

“We are currently operating at peak volumes and the system is working well. As soon as things settle back a little, we will review what we have learnt so far about the system and then seek to exploit it further, with the support of Nulogy.”

Josephine Coombe, Managing Director, Nulogy UK, said: “We’re thrilled to be welcoming APS to the community of Nulogy-powered co-packers in the UK and delighted that our teams worked together successfully to enable a smooth remote implementation given the constraints posed by the pandemic.

“As FMCG brands increasingly seek highly collaborative and responsive external supply chain partners, a robust digital backbone for co-packing operations is increasingly a competitive advantage.

“We look forward to helping APS reap the benefits of this advantage and deliver the agile performance required to meet their customers’ operational and quality standards, even during these uncertain times.”

The pandemic has meant many FMCG-focused contract manufacturing and packing providers have had to adjust and evolve their operations. Recognising this, Nulogy moved quickly to ensure its software not only provides robust labour management, inventory and traceability controls, but also allows contract packers to better manage infection control protocols on the shop floor.